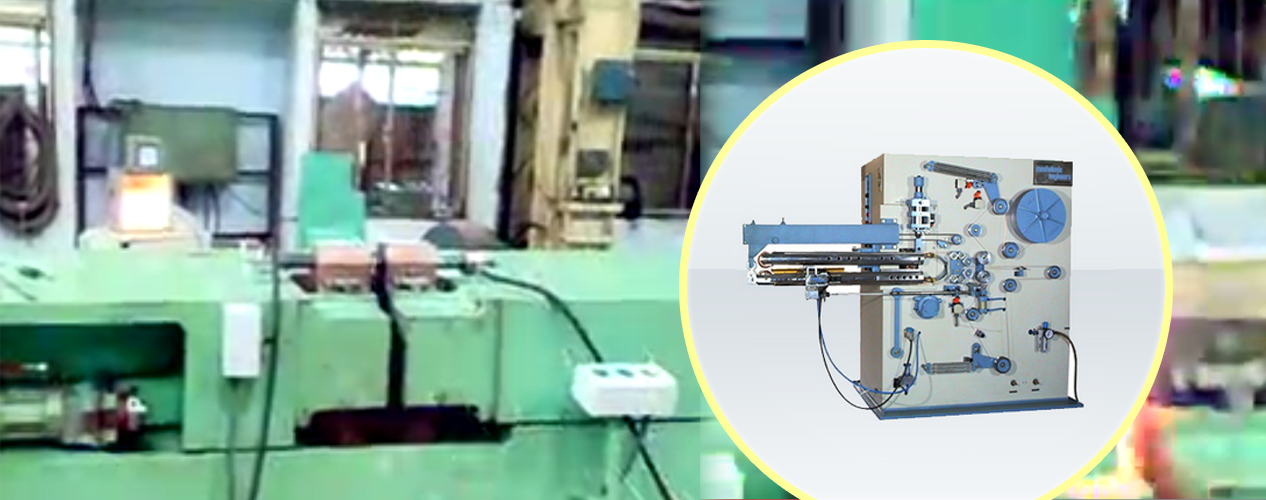

Solidification Machine

|

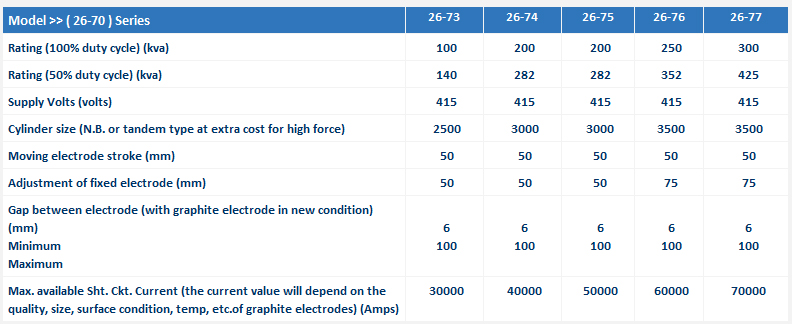

| Technical Data |

|

Solidification Machine

To heat and solidify copper flexible link manufactured from bunch/stack of copper-foils, used in Electrical and Chemical Industries.

Specifications: Machine Type :

The machine is sturdy, all welded steel plate fabrication, and suitably welded and stiffened at points of stress to minimise deflection. The transformer and D.C. Rectifier assembly fitted inside of the body. The pneumatic cylinder mounted on the right hand side to give horizontal movement of the ram guide through precision slides with graphite heating / forging electrodes with water-pump to cool un-heated portions. All internal parts are easily accessible. Transformer Rectifier Set :

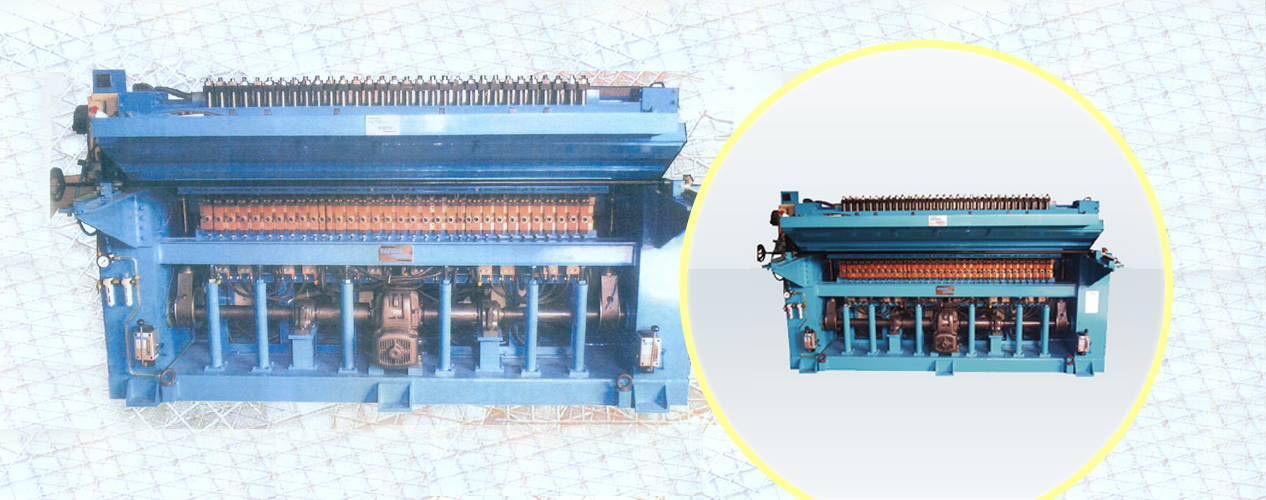

The direct current rectifier system consists of high power silicon rectifier to rectify the alternating current available on the secondary of transformer to direct current. It has large number of basic rectifier pellets connected in between the secondary of transformer and the output bus-bars. These pallets are clamped in specially designed clamping system which ensures the correct amount of clamping pressure and uniform contact. Suitable water cooling system designed into these clamps ensures efficient cooling of rectifier elements. Current Control By Transformer Taps: Heat Initiation : Electrode Control System:

Machine is provide with air filter, air lubricator, air pressure regulating valve, pressure gauge, and all internal air connections. Adjustment of Electrode Force: By air pressure regulating valve provided on the machine.

Adjustment of Electrode Stroke: By horizontal adjustment of the stationary electrode.

Platens:

Electrodes:

Operation : Copper foils these conditions are fed to the machine. The portion to be forged (generally ends) is held on fixed electrode and clamp foot switch is initiated. RHS moving electrode clamps the flexible link under pressure with other end dipped in water-pump. Current switch is initiated. The main magnetic contractor gets ON and transformer is energised. Graphite electrodes start heating to cherry red colour and heat gets conducted to the interior of links and raise temp. of on-off current foot switch operation. These pulses provide a constant heat flow from electrodes into the flexible link. (NEVER ALLOW THE ELECTRODE TO GET BRIGHT-WHITE HOT OR ELSE ENDS OF COPPER FOILS WILL MELT OFF).

During the operation whatever heat is conducted to other areas of flexible link is drained off by continuous flow water in tank by this allowing to avoid annealing of copper foils. When fully forged force to continue till graphite electrode colour comes to normal black. Release the clamp and link will fall in water-sump permitting it to be cooled. Safety Provision:

Cooling System:

Electro -Magnetic Contractor: Machine provide with electro-magnetic heavy duty contractor for switching on/off of main transformer. |