Seam Welder for Steel Mill

|

||

| Technical Data : | ||

|

||

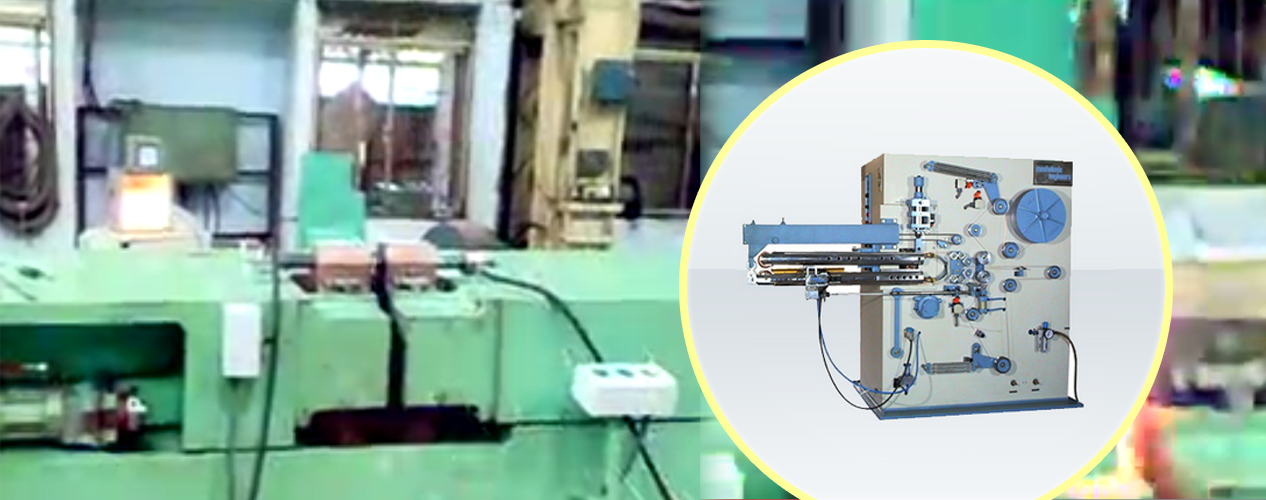

Seam Welder for Steel Mill This special purpose moving head seam welder is specially designed for steel strip joining in continuous processing plants such as galvanizing plants, coating plants and rolling mills. This machine is primarily used for high speed operation providing minimum pause in line for coil joining. The high strength limited overlap joint produced in the strip is quick and economical for processing. Construction: The welding head consists of two weld wheel holders with silver contacts, independently mounted on individual guided rams. One of the weld wheels is used for welding, whilst the other is used for the return path. The independent mounting ensures that the requisite welding force can be applied to the weld wheel and the return path wheel. The welding transformer along with the welding head is trolley mounted. His ensures the same electrical path throughout the width of the strip being joined. A variable drive is provided to the trolley to achieve the welding speed. The is suspended from a track on the top part of machine frame. A rigid beam at the bottom provides support for the backup for the strips at the bottom. The strips are clamped along the full width a cylinder at either end to provide uniform clamping force. The clamps retract to provide clear passage for the strip. Control: Optional Accessories (At extra cost) Re-squaring Shear: Tail-end Positioner: Weld Identification Hole Punch: Notcher (Optional): A notcher is provided on either side of the sheet. This is used to provide a notch at either end of the joint when sheets of different widths are joined to enable smooth entry of a wider head end of a new coil or to enable setting of slitter on a narrower head end of new coil. The notcher shall be capable of notching a joint where the difference is width of the two sheets to be joined shall be 150 mm at each notcher. Edge sensors are provided to automatically position the notcher with respect to the sheet edge when initited. This shall be used alongwith the puller for precise positioning of joint in centre of notcher when required. Four Point Centring (Optional): The four point centring mechanism consists of two sets of vertical rollers mounted on LH and RH lead screws on positioning drive shaft. These rollers also have edge sensors which determine the position of each roller with respect to the sheet edge. When all the sensors (or any three) sense the sheet, the sheet will have been centered. This set of centring rollers are required one each on the head end side and tail end side of the welding position for the two sheets to be joined. Inerlock with Line Computer (Optional): Facility for interlock with line computer is provided by suitable interfacing of hardware and software interlocks. |

||