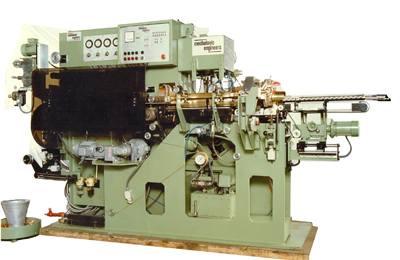

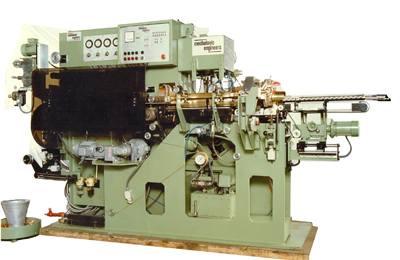

Body Maker

Mechelonic Engineers has now introduced the second generation, fully automatic container side seam welding machine with medium speed production. Machelonic engineers system of container welding is well established for producing continuous, constant narrow weld at optimum working speed, using copper wire as intermediate electrodes.

Applications

The machine is designed for medium speed automatic welding of tin sheets in container manufacturing. This machine has flexibility of design to accommodate different sizes of cans from 72 to 450mm length(body height)

Features

The machine is fully automatic combining various stages of manufacturing like destacker feeder, flexer, roll forming, overlapping the edges for welding of side seam, transport to welding station, wire drive, welding station, ejection of welding shells and wire collector.

Construction

Compact main frame of welded construction having streamlined appearance. The main transformer, variable speed drives, electronic control system etc. are enclosed in the frame and are easily

accessible for serving.

Main transformer

Specially designed class ‘F’ insulated transformer, water cooled and fully tropicalised for withstanding continuous operation.

Destacker Feeder

Pneumatically operated oscillating arm with a set of vacuum suckers, provided on the machine destacks the blanks and delivers them to flexer rollers. This process is monitored by electronic control system to give command for further operation. A hydraulically operated table is provided for stacking body blanks. This table automatically raises to adjust the level of body blanks for feeding to the flexer. The machine is provided with manetic sheet floaters and air jet separators to facilitate single sheet feed to flexer rollers.

Flexer

The body blanks fed to flexing rollers are flexed and moved to roll former. Flexure is provided with rubber coated rollers to avoid damage to printed surface of tin sheet.

Roll Former

The flex banks are automatically moved into the roll former and rolled into desired shapes. Roll former has arrangement to adjust the body rolling diameter within specified range.

Centering Flaps

The rolls blacks are collected by a set of pneumatically operated flaps, which also guides edges of rolled body in catch bar. A separate set of flaps are required for each range of body diameter.

Crown Assembly

The crown assembly near welding station controls exact diameter of body before welding. This assembly can be calibrated outside the machine on a setting mandrel.

Calibrating Ring

for welding with narrow overlap (0.5mm), calibrating ring assembly provided on the machine will maintain parallel overlap.

One set consisting of crown assembly, crown setting mandrel, centering flaps and calibrating ring will be provided with machine for a specific size of can as standard. Other sizes will be available on additional cost.

Upper Arm

The upper arm is manufactured from special grade high tensile brass of suitable cross section to minimize any deflection during normal operation. The upper weld wheel and Z- bar are fixed to this arm. Arm is water cooled.

Note: tooling for 301 and 302 at extra cost: Tooling for 301 and 307 together with a small arm could be supplied as aspecial case provided the customer uses Tin plates of Temper T3.

Catch- Bar and Z-Bar

The machine is provided with catch-bar and Z-bar to control overlap and also to guide the shell, while welding.

Welding Station

Welding station consists of two anti-fiction type weld wheels, made of special copper alloy with mercury contacts. These weld wheels are water cooled. A specially made weld wheel holder for lower weld wheel is provided. Welding pressure is provided by lower weld wheel. A single copper wire running over weld weld wheels act as intermediate electrode. The formed body of can is transported to welding station. The arrival of can is sensed through an electronic system and welding initiates and completes automatically.

In this machine welding is at the bottom of can.

Wire Flattening Unit

A controlled drive with rollers, flatten the copper wire to the required flatness before entering the wire feeding system.

Wire Feeding System

An accurate variable speed drive with electromagnetic clutch brake system and control wire tensioning devices provide positive and precise fed control of copper wire.

Ejection of Welded Shells

Welding shells are received on a magnetic conveyor and ejected on the main conveyor.

Wire controlling System

The copper wire used as the intermediate electrode for welding is wound on a re-coiler.

Control Panel

A centralizedcontrol panel is provided with facilities like operating switches, pilot lamps, ammeter, current fine setting, batch counter and continuous counter of cans. Machine is also provided with additional facilities like single cycle mode and setting up mode.

Operating cycle

Load body blanks on the table, adjust parameters on the machine, operate the start switch. The machine instantaneously starts and continues to weld the body blanks. The operator has to only ensure that the destacker table has enough stock of body blanks. The automatic function includes picking up of the body blanks, flexing roll forming, guide to the catch- bar and then to Z-bar and welding at the welding station. The welded bodies are automatically ejected out.

Safety Features

Safety features like No Wire Detector, Wire Cut-off Detector, No Can Detector, No Guard Detector Weld Wheel Position Detector are part of the machine.

Side Stripping System

The Machine can be provided with Nordson internal and external liquid lacker stripping system, alongwith take of conveyor and suitable cutting system at additional cost. |