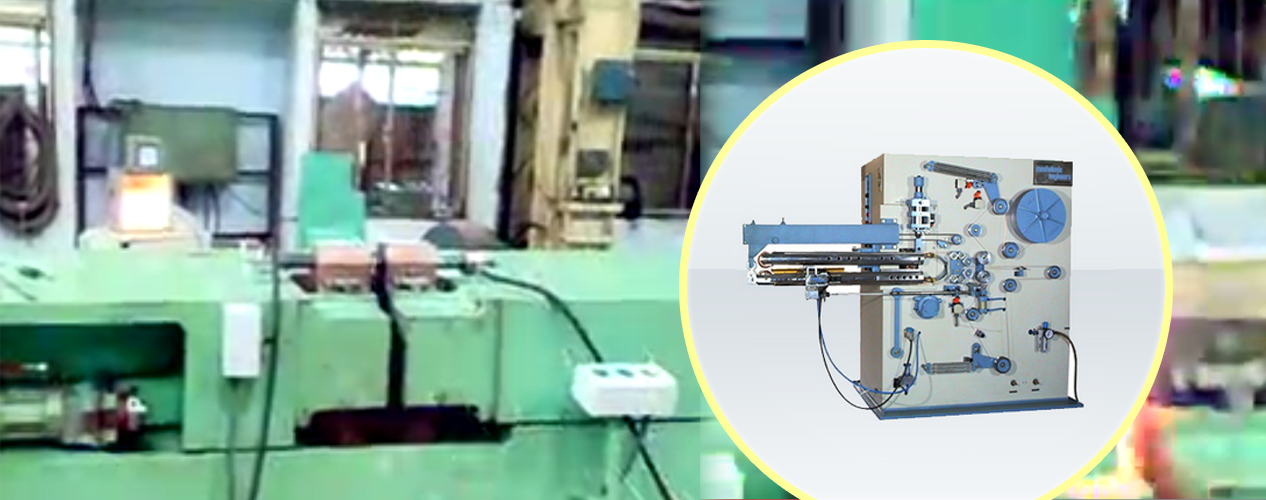

Multi-Head Spot Welder

|

||

| Technical Data : | ||

|

||

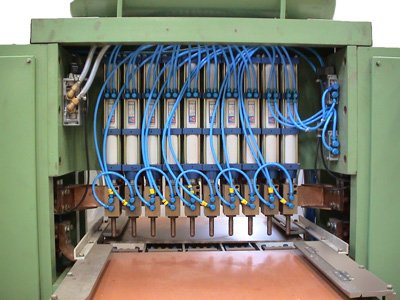

Multi-Head Spot Welder Multi-Head Spot Welding Machine is specially designed for welding floor tiles fabricated assemblies. The machine is equipped with ten welding heads, five welding transformers, microprocessor based control, pneumatically actuated welding heads and job guides. Operation: The ten welding heads are divided into three groups. The middle six heads are in one group. The two outer heads (first from each end) are in one group and the immediate next heads are in group. A selector switch(s) determine which heads are actuated when the foot-switch is initiated. This permits selected group from being activated when the corresponding spots are not required. Construction: Welder Control: Cooling systems: The transformers, electrodes and thyristors are water cooled and provided with inlet manifold and outlet manifold. Alternately, the discharge to an open drain pot, for visual observation of flow, can be provided. Electrode Control System: Heavy–duty pneumatic cylinders actuate the electrodes. The cylinders are operated through solenoid valves by the weld control. Compressed air at 2 kg/cm2 to 7 kg/cm2 acting through the pneumatic cylinders provides the electrode force. Machine is provided with air filters, regulators with gauge, lubricator etc, together with internal air connections. Adjustments of Welding Force: The welding force is adjusted by setting the air pressure in the welding head cylinder wit the help of the regulators. |

||