Capacitor Discharge Stud Welders

Capacitor discharge stud welding uses a low voltage capacitor storage system as power source. There are two different welding systems depending on the material:

1. Initial-gap, in which the stud is initially positioned away from the surface of the work-piece. Weld-time is extreme short (<0.001sec).

Material- Aluminium.

2.Initial-contact, in which the stud is initially in contact with the work-piece. Weld time is 0.001 – 0.003 sec.

Material- Mild Steel, Inox, Brass, Titan etc

A flux or protective atmosphere is not required. The short welding time prevents heat builtup and permits welding of studs to very thin metal sections without discoloration and burn thru. Minimum weld penetration permits many dissimilar metal to be welded with acceptable strengths and metallurgical characteristics. Also depending upon the section thickness, paint or vinyl coatings on the other side of welded surface are not damaged. The stud-welding process is very simple. No special educated people are required.

Capacitor-Discharge(CD) Studs:

The welding end is provided with a small cylindrical or conical tip. that is used to initiate the welding arc. Tip design is extremely important since the tip and the shape will influence weld strength and other factors. Basic stud design is given in DIN EN ISO- standard 13918 (1998). Besides the three basic designs- Threaded Stud, Unthreaded Stud and tapped Stud. It gives a lot of special designs and coatings for various applications.

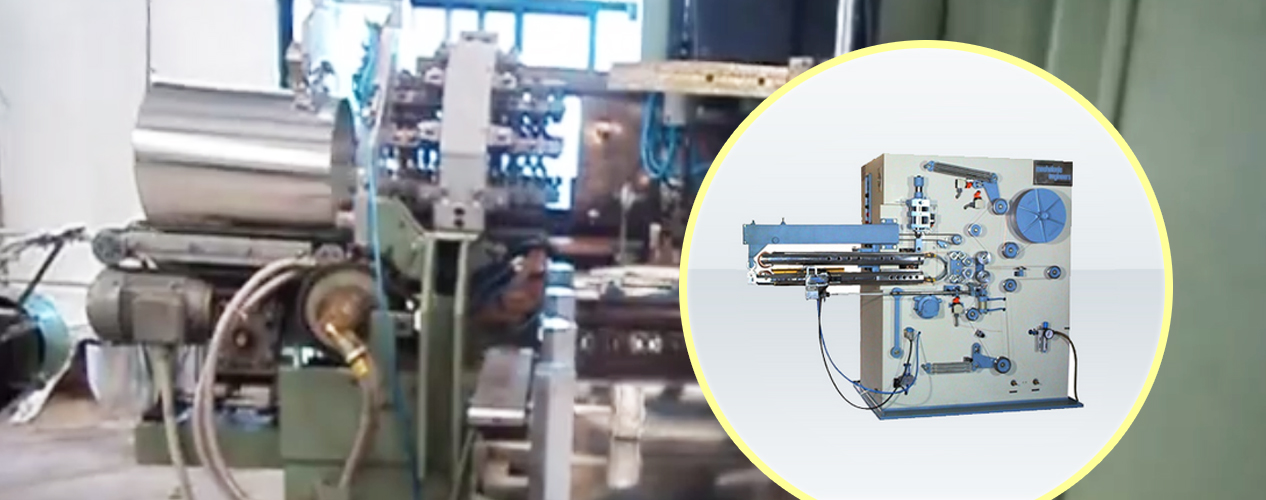

CD-Studwelder 1066

The easy to use solid state light weight unit for the stud welding process, as described. All studwelding applications upto 8 mm stud-diameter are approved. Simple monitoring of all functions by LED-indicators. The unit is designed for portable and stationary applications, has a temperature control fan, a safety switching system. The main voltage fluctuation doesn’t have any affect to the welding energy. Service and maintenance shall be simple and easy cause the modular construction of the unit.

The equipment consists of:

1 CD-Studwelder 1066, as described.

1 Contact-gun,

6 Cable of 5 m length (Opt.: gap-gun)

2 Earth-cable

2 Cable of 5 m length with grip.

5 Chucks with dia 3.4,5,6 and 8 mm

1 Tool for changing chucks

1 Service manual. |